Modern Tools for Smart Grid Automation Training

By Grigore Stamatescu, Iulia Stamatescu, Nicoleta Arghira, Ioana Fagarasan

Effective training of future smart grid technicians and engineers requires modern tools that keep up with and anticipate the growing adaption of advanced IT and automation technologies in the field. New smart grid projects require multi-disciplinary teams composed of power systems engineers, automation engineers and software engineers to handle the growing complexity and interdependence of multiple subsystems and an integrated perspective on process logic, control aspects and technology interoperability. Development of suitable educational instruments is thus required that considers this paradigm shift in increasing levels of complexity and engages the students with the learning content while allowing the means for both hands-on laboratory experimentation and remote visualization and operation in an e-learning context.

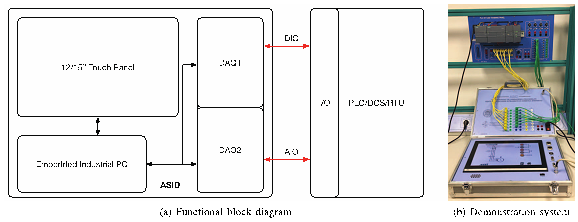

We illustrate our recent experience in developing such instruments in the form of a process simulation equipment suitable for vendor agnostic PLC trainings with rich user interface and process model representation and realistic signal feedback and debugging. Starting point is the development of a simulation program that models various processes present in the smart grid and the mapping of I/O signals: discrete and continuous sensor measurements and control signals. Industry-standard physical signals: 24V for digital and 0-10V for analog inputs and outputs, are interfaced with a separate control unit where the students must implement the control logic according to the process description and expected behavior. This type of setup allows a clear association with the process by the students who can measure the signals and debug incorrect implementation or simulated faults. Simulation applications are developed using the C# programming languages and run on an embedded industrial PC through the Windows 10 IoT operating systems. Suitable communication drivers are integrated for the ModBus data acquisition boards (DAQ) that acquire and generate the required signals. The control logic implementation depends on the manufacturer of the hardware e.g. Step 7 TIA Portal, Codesys, FactoryTalk, and others. Figure 1 shows the conceptual design and the physical realization of the demonstrator controlled by a Siemens S7-1200 family PLC unit.

Figure 1 Educational Process Simulator for the Energy Field [1]

Figure 1 Educational Process Simulator for the Energy Field [1]

This development was carried out together with an industrial partner during the research and technology transfer project ASID – Advanced Process Control System for Intelligent Specialization in the Energy Field [2].

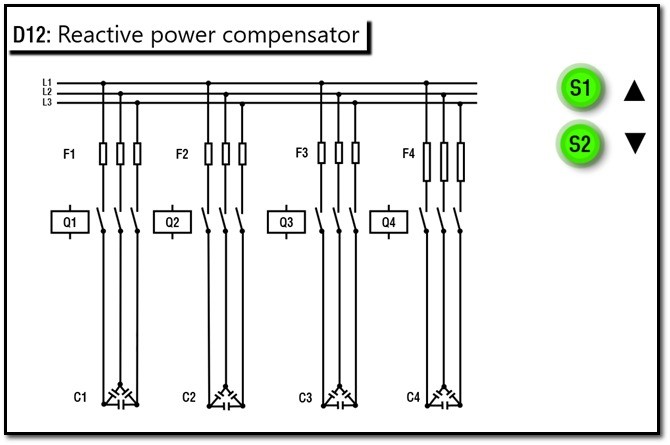

One reference basic application for control of energy processes is described which models the reactive power compensation of a large industrial consumer. The percentage of reactive current within the total current amount consumed by the machinery equipment of a company department depends on the number of devices in operation. For reactive power compensation and increased electricity transmission efficiency, a PLC system must be designed to connect groups of capacitors to the power network as required. Each time the button S1 is pressed, a capacitor group is added to the main network, and each time S2 is pressed, a group is removed. The connection is done via contactors Q1 to Q4. The user interface is shown in Figure 2. Other types of processes, relevant to the smart grid, can include electrical drive systems, digital power system protections (automatic reclosing / 3-phase automatic reclosing), and energy management systems at the grid and consumer levels.

Figure 2 Simulated Process UI Example

Figure 2 Simulated Process UI Example

The presented system is now used for laboratory training at the University Politehnica of Bucharest starting with 3rd year BSc courses: Automation Systems – Power Engineering Faculty, 4th years BSc courses: Control and Automation of Energy Systems – Power Engineering Faculty, up to the MSc level: Advanced Techniques for Process Control – Automatic Control and Computers Faculty. Using well documented hardware components and open-source software libraries, e.g. libmodbus for ModBus industrial communication, enables the students to easily replicate the system design and extend the platform with new simulation models during the semester and for graduation projects. More than 50+ processes have been developed so far.

The process simulator can also serve as a practical solution for professional and life-long training programs either as a general-purpose training solution for automation or for domain-specific courses like smart grid automation, covering production, transmission, distribution and, demand-side applications. Through embedded webservers running on new generation PLCs, the process variables and program execution can be monitored remotely which in turn, increases the productivity of the training sessions.

In the context of the current push towards extended use of the remote learning solutions, we envision the virtualization of such set-ups in two alternative ways: 1) if the student has access to the physical automation device, the simulated process can be virtualized while providing real-time control feedback over the internet 2) if the student does not have access to the physical automation device, both the simulated device and programming and deployment of the simulated PLC run remotely with highlighting key aspects of the program execution.Regarding the implementation of such solutions, using a generic programming language for the development of the individual processes, the simulation software can be deployed in Linux-based sandboxed environments that run in the cloud. The control device can also be simulated using software products such as Siemens PLCSIM Advanced, while the physical signals can be embedded into new IoT publish/subscribe protocols such as MQTT which are supported by the newer generations of automation devices.

References

- I. Stamatescu, G. Stamatescu, I. Fagarasan, N. Arghira, V. Calofir and S. S. Iliescu, "ASID: Advanced system for process control towards intelligent specialization in the power engineering field," 2017 9th IEEE International Conference on Intelligent Data Acquisition and Advanced Computing Systems: Technology and Applications (IDAACS), Bucharest, 2017, pp. 475-480, doi: 10.1109/IDAACS.2017.8095126.

- ASID Project Website, Available on-line: https://shiva.pub.ro/asid

This article edited by Pardis Khayyer

For a downloadable copy of the October 2020 eNewsletter which includes this article, please visit the IEEE Smart Grid Resource Center.

To have the Bulletin delivered monthly to your inbox, join the IEEE Smart Grid Community.

Past Issues

To view archived articles, and issues, which deliver rich insight into the forces shaping the future of the smart grid. Older Bulletins (formerly eNewsletter) can be found here. To download full issues, visit the publications section of the IEEE Smart Grid Resource Center.