Green Hydrogen: Challenges for Commercialization

Written by Sivapriya Bhagavathy and Jagruti Thakur

Hydrogen has been in use for many decades in sectors like refining and chemical industries. However, its use as an energy source has started receiving increased interest only in recent years. As this interest and end-use grow, the demand for hydrogen will also grow with an expected compound annual growth rate of 5.48% from 2019 to 2025 [1].

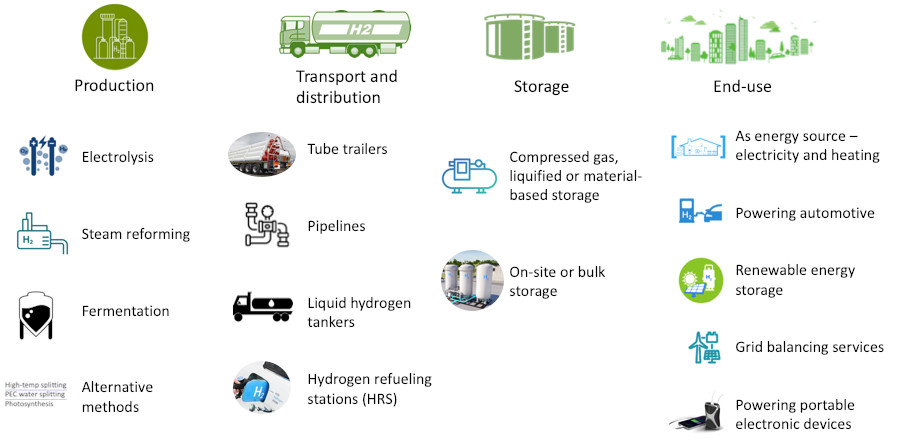

Hydrogen has been in use for many decades in sectors like refining and chemical industries. However, its use as an energy source has started receiving increased interest only in recent years. As this interest and end-use grow, the demand for hydrogen will also grow with an expected compound annual growth rate of 5.48% from 2019 to 2025 [1]. To ensure that this demand for hydrogen is met sustainably and with minimal impact on the environment, the production of hydrogen should have minimal or no carbon emissions. Such hydrogen, referred to as Green Hydrogen, can be produced from renewables, nuclear or fossil fuels with carbon capture, utilization and storage (CCUS). Emissions from green hydrogen production can range from 43 gCO2e/kg of hydrogen produced using electrolysis to 9.3 kgCO2e/kg of hydrogen produced using steam reforming process without carbon capture [2], [3]. To provide a context, one kg of hydrogen has an energy equivalent of one gallon of gasoline which produces 9.1 kgCO2 during combustion. The major end use of transport using fuel cells have an efficiency of more than 50% (60% for conversion of hydrogen into electricity and 90% for conversion of electricity into kinetic power) as against the 25% efficiency of internal combustion engines [4]. That is, for similar miles, emissions from hydrogen is half that of gasoline considering production to tailpipe. Commercialization and deployment of green hydrogen on a large-scale faces significant challenges. This work, therefore, highlights the current challenges for the commercialization of green hydrogen across the four phases (shown in Figure 1): production, storage, transport and distribution, and end-use. The challenges highlighted here are based on the high-level review of more than 200 completed or on-going hydrogen projects across the globe [5].

Figure 1: Production to end-use of hydrogen

1. Green Hydrogen Production

Green hydrogen is commonly produced by electrolysis, steam reforming and fermentation. A brief description of the production method and the associated challenges are as follows.

- Electrolysis: Electricity is used in this process to split water into hydrogen and oxygen. This process has an efficiency of around 60-80% by calorific value [6]. The commercialization and large-scale deployment challenges of electrolysis are as follows.

- Need for improved overall energy efficiency.

- Need for additional onsite compressors.

- Low lifetime of electrolysers (<5 years).

- Steam reforming: Steam reforming can be used to convert methane, liquids derived from biomass resources, and biogas to hydrogen. This process provides the advantage of being a mature technology and easy transportation of input fuels with conversion on-site or at refueling stations [7]. If methane or natural gas is used, then additional carbon capture mechanisms should be in place to limit the net emissions. The challenges associated with this method are as follows.

- High complexity of the reforming process due to the relatively larger molecule sizes of biomass-derived liquids than fossil fuels.

- Low overall efficiency of the process (currently around 40% [8]).

- The reformer should be able to adapt to different compositions and flow rates of biogas or biofuels and local heat sources.

- Fermentation: In this process, sugar-rich feedstock from biomass is fermented to produce hydrogen using microbes either through direct hydrogen fermentation or microbial electrolysis cells (MECs). The challenges associated with fermentation are as follows.

- Low overall efficiency of the biogas reactor.

- Low rates and yields of hydrogen production from fermentation.

- Scaling-up of MEC systems while maintaining production rates and system efficiencies are not yet proven.

A series of alternative production methods to split water is also under development. For example, high-temperature water splitting, photobiological water splitting, photoelectrochemical water splitting, low-temperature hydrogen production by replication of photosynthesis, and extraction of hydrogen byproduct from chemical industries.

2. Storage of Hydrogen

Hydrogen is stored typically by three methods: compression, cooling, or hybrid. Material based hydrogen storage is also being developed in the form of solids, liquids, or surface-based materials. Hydrogen can be stored on-site or bulk where in on-site storage is used for production plants and end-use applications, and bulk storage is used for large amounts of storage in geographical hydrogen storage (e.g. in salt caverns, abandoned mines etc.). However, there are some challenges with the storage of hydrogen as discussed below.

- High energy requirement in compressed hydrogen storage, due to low specific gravity.

- Temperature and pressure requirements while storing hydrogen in solid form.

- Design aspects, legal issues, social concerns, and high cost.

- Low durability of materials (fiber, metals, polymers etc.) for storage and potential chemical reactions raise safety concerns.

- Bulk storage at geographic features may contaminate the hydrogen creating the need for further purification before end-use.

3. Transport and Distribution of Hydrogen

Hydrogen can be either used onsite or transported and distributed to the end-user locations [9]. The common methods of transport and distribution of hydrogen are pipelines, high-pressure tube trailers, and liquified hydrogen tankers. Pipelines are currently the least expensive way and are already in use near large refineries and chemical plants. Liquified hydrogen tankers transport the hydrogen that has been cooled to a temperature where it becomes a liquid. This increases the density of distributed hydrogen, making it more efficient for transportation than high-pressure tube trailers. However, if the delivery and consumption rates are not matched, the compressed hydrogen will evaporate causing significant losses and ineffective utilization. The challenges in transport and distribution of hydrogen are as follows.

- Existing hydrogen transportation pipeline infrastructure is not sufficient to meet future demand.

- Existing natural gas pipelines cannot be directly used for hydrogen due to embrittlement. Though mixing of hydrogen with natural gas is considered an option, it significantly affects the life of the pipelines even at 5% concentration by volume [10].

- Lack of fine control of the flow of hydrogen at refueling stations. The flow of hydrogen has a significant impact on evaporation and losses of the system.

- Fluctuations in temperature during fast transfers of compressed hydrogen has to be controlled optimally to minimize losses and prevent thermal instability.

- The network of hydrogen refueling stations has to be increased.

Alternate ways for transporting hydrogen, for example using liquid organic materials as hydrogen carriers, are being researched to enable a low-cost high energy density transfer of hydrogen.

4. End-use of Hydrogen

Hydrogen can service multiple end-uses with its major application in energy use for the supply of electricity or heating through combined heat and power units, power for remote or off-grid applications like telecom towers, automotive sector, etc. Hydrogen based Fuel Cell Electric Vehicles have higher efficiency than gasoline-based vehicles, long driving range, and no emissions, thus offering a potential solution for future sustainable transportation. The use of hydrogen fuel cells for portable applications in portable electronic devices like mobile phones and personal computers are being explored. There are various advantages of fuel cells over battery systems like a longer lifetime, zero end-use emission, higher efficiency, cleaner fuel (hydrogen), lower weight etc. However, when it comes to end-use there are several challenges which need to be addressed before the large-scale commercialization of hydrogen as discussed below.

- Need for weight, volume, and cost minimization of compressed hydrogen gas tanks for vehicles and fuel cell stacks.

- Efficiency, degradation issues, durability, resiliency, size as well as power, and current densities of the fuel cell needs improvement.

- Lack of systems monitoring the performance and state of health of the system.

- High complexity of the fuel cell system especially with thermal and water management, purification, and humidification.

- Low run time of fuel cells for portable electronic devices has to be improved without increasing the size [11].

The challenges for commercialization that are relevant across all phases are as follows.

- High overall costs of the system including capital, operational, maintenance, and running costs.

- Supply chain development across all the pillars is still in its nascent phase.

- Integration with other energy vectors using information and communication infrastructure.

- Need for legal and administrative adherence, certification mechanisms, recommendations, and regulations for different components of the system.

- Low user acceptance and social awareness.

- Developing after-sales service for hydrogen technology.

In summary, green hydrogen has the potential to act as a lever to decarbonize the energy sector, especially the hard to reach areas of heating and heavy-duty transport. The advancement in digitalization offers various opportunities to harness Hydrogen as one of the prominent sources for energy and storage for energy needs. However, for maximizing the potential and commercialization, challenges spread across all four phases have to be addressed.

References:

- “Hydrogen Market Share, Size and Industry Growth Analysis 2019 - 2025.” https://www.industryarc.com/Research/Hydrogen-Market-Research-501664 (accessed Dec. 30, 2020).

- “Estimating The Carbon Footprint Of Hydrogen Production.” https://www.forbes.com/sites/rrapier/2020/06/06/estimating-the-carbon-footprint-of-hydrogen-production/?sh=7d67e01b24bd (accessed Jan. 30, 2021).

- P. L. Spath and M. K. Mann, “Life Cycle Assessment of Renewable Hydrogen Production via Wind/Electrolysis: Milestone Completion Report,” 2004. Accessed: Jan. 30, 2021. [Online]. Available: http://www.osti.gov/bridge.

- “Hydrogen fuel cell: overview of where we’re at in hydrocarbon replacement.” https://www.power-technology.com/comment/standing-at-the-precipice-of-the-hydrogen-economy/ (accessed Jan. 30, 2021).

- “Hydrogen.” https://hydrogeneurope.eu/index.php/projects (accessed Dec. 30, 2020).

- “Electrolysers | Hydrogen.” https://hydrogeneurope.eu/electrolysers (accessed Dec. 31, 2020).

- “Hydrogen Production: Biomass-Derived Liquid Reforming | Department of Energy.” https://www.energy.gov/eere/fuelcells/hydrogen-production-biomass-derived-liquid-reforming (accessed Dec. 21, 2020).

- P. Sarothi Roy, J. Song, K. Kim, C. Seung Park, and A. S. Raju, “UC Riverside 2018 Publications Title CO2 conversion to syngas through the steam-biogas reforming process,” J. CO2 Util., vol. 25, pp. 275–282, 2018, doi: 10.1016/j.jcou.2018.04.013.

- “Alternative Fuels Data Center: Hydrogen Production and Distribution.” https://afdc.energy.gov/fuels/hydrogen_production.html (accessed Dec. 30, 2020).

- B. Meng et al., “Hydrogen effects on X80 pipeline steel in high-pressure natural gas/hydrogen mixtures,” Int. J. Hydrogen Energy, vol. 42, no. 11, pp. 7404–7412, Mar. 2017, doi: 10.1016/j.ijhydene.2016.05.145.

- P. P. Kundu and K. Dutta, “Hydrogen fuel cells for portable applications,” in Compendium of Hydrogen Energy, Elsevier, 2016, pp. 111–131.

This article edited by Mehrdad Boloorchi

For a downloadable copy of the February 2021 eNewsletter which includes this article, please visit the IEEE Smart Grid Resource Center.

To have the Bulletin delivered monthly to your inbox, join the IEEE Smart Grid Community.

Past Issues

To view archived articles, and issues, which deliver rich insight into the forces shaping the future of the smart grid. Older Bulletins (formerly eNewsletter) can be found here. To download full issues, visit the publications section of the IEEE Smart Grid Resource Center.